In the modern landscape of manufacturing, Smart Factories powered by Industry 4.0 solutions are ushering in a new era of efficiency, flexibility, and innovation. These cutting-edge facilities leverage advanced technologies to optimize operations, reduce costs, and enhance overall productivity. Let’s explore how Smart Factories are revolutionizing industries worldwide.

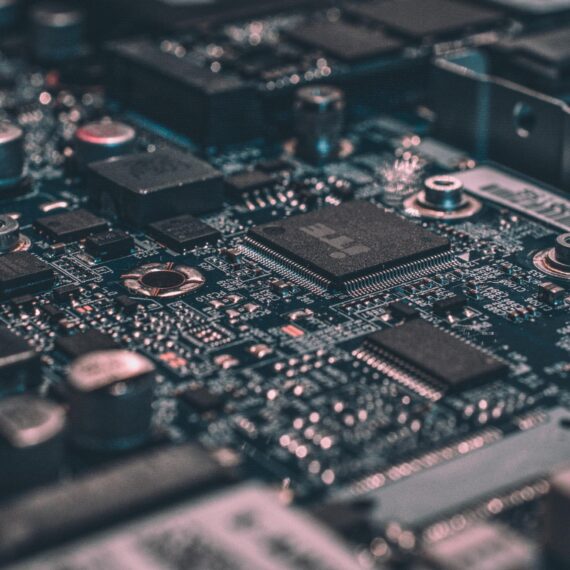

A Smart Factory is a digitally connected, data-driven manufacturing facility that leverages a range of technologies, including the Internet of Things (IoT), artificial intelligence (AI), big data analytics, and automation, to streamline and enhance production processes. These facilities are characterized by their ability to collect real-time data, make intelligent decisions, and adapt swiftly to changing demands.

These sensors are embedded throughout the factory to gather data from machines, equipment, and processes.

High-speed, reliable networks enable seamless communication between devices and systems within the factory.

Advanced analytics tools process and analyze the vast amounts of data generated in real time, providing actionable insights.

Automation systems and robots perform repetitive tasks, improving precision and efficiency.

Virtual replicas of physical equipment or processes help monitor and optimize operations.

AI algorithms optimize production, quality control, and predictive maintenance.

Workers interact with technology, ensuring safety and efficiency.

Smart Factories optimize processes, reduce waste, and minimize downtime, resulting in increased productivity.

Real-time monitoring and AI-driven quality control enhance product quality and consistency.

Efficiency gains and reduced waste lead to cost savings.

Smart Factories can quickly adapt to changing production demands and market trends.

Equipment sensors enable predictive maintenance, reducing unplanned downtime.

Reduced energy consumption and waste contribute to environmental sustainability.

Smart Factories and Industry 4.0 solutions are reshaping industries, offering greater efficiency, quality, and agility. As technology continues to evolve, the potential for innovation and growth in the manufacturing sector is boundless, making Smart Factories a cornerstone of the future of manufacturing.